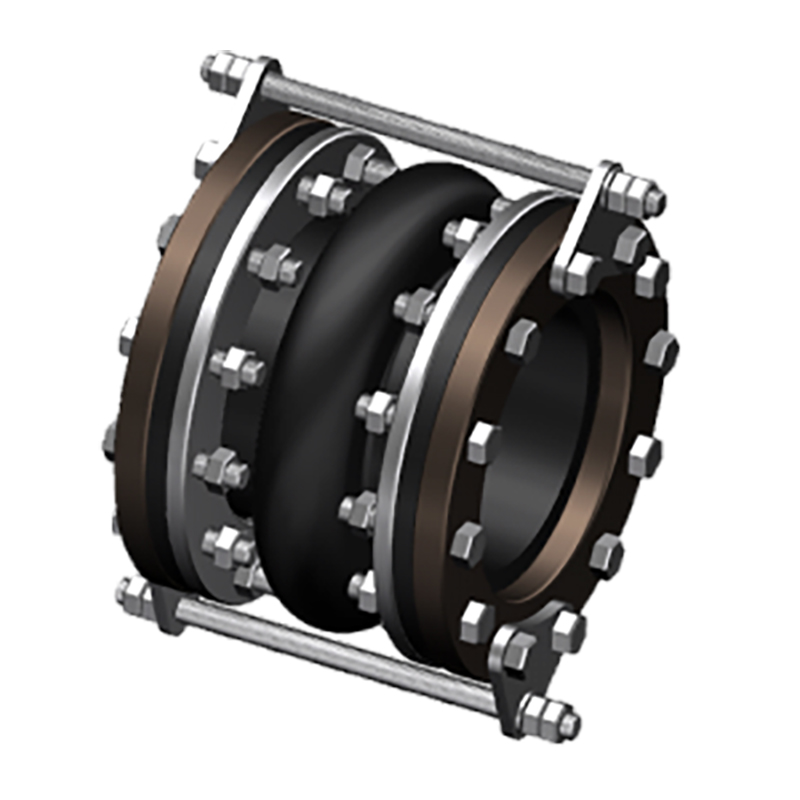

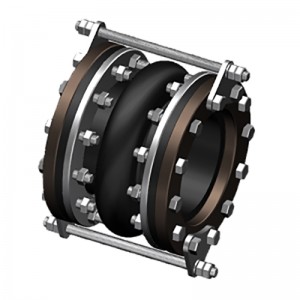

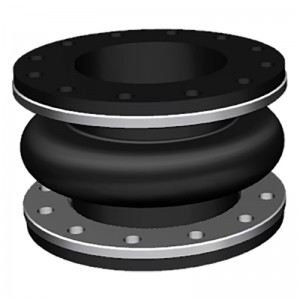

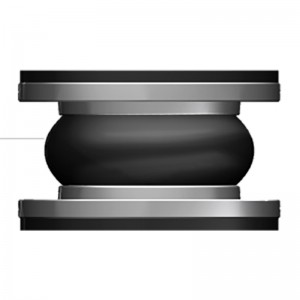

A-4 ~Spool Type Rubber Expansion Joint

Our available goods

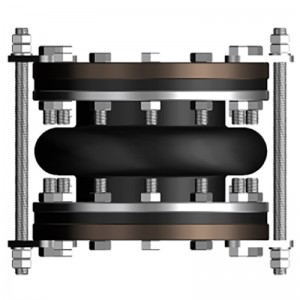

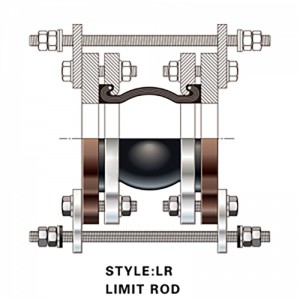

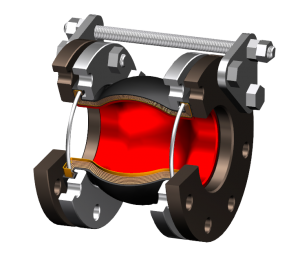

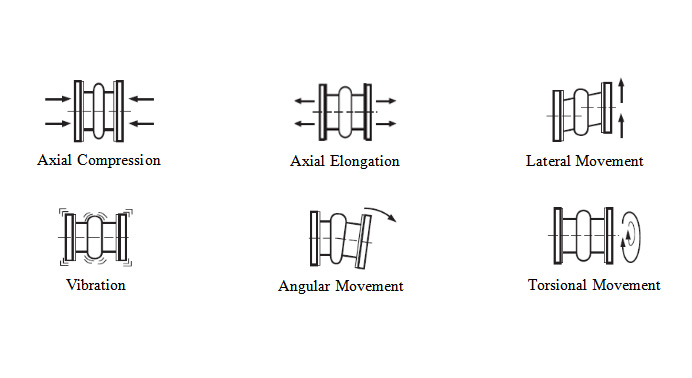

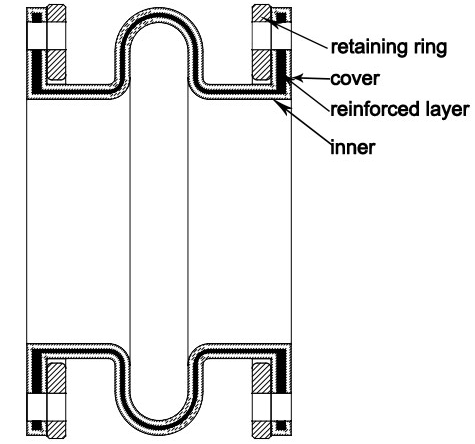

The spool type rubber joint is molded type, with a metal collar reinforced at the neck of the body. The ST stype uses a light reaining ring to support the integral flange. STF is filled arch, with 50% of the ST allowed movements, but it has 4 times spring rates than hollow arch.

|

Specifications |

I |

II |

III |

|

Working Pressure Mpa (Kgf/Cm2) |

1Mpa (10) |

1.6 (16) |

2.5 (25) |

|

Test Pressure |

1.5Mpa |

2.4Mpa |

3.75Mpa |

|

Burst Pressure Mpa (Kgf/Cm2) |

3 (30) |

4.8 (48) |

5.5 (55) |

|

Vacuum Kpa (Kgf/Cm2) |

53 (400) |

86(660) |

100 (750) |

|

Materials |

EPDM/NBR/SBR/NR/Butyl/Neo/Lined with PTFE |

||

|

Diameter Range |

DN15-DN600 (11/2"-24") |

||

|

Connection Method |

FLANGE\THREAD\CLAMP |

||

|

Flanges Dimensions |

DIN, EN,ANSI, BS, JIS and other standards |

||

|

Applicable Medium |

Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. |

||

|

Loading Port: |

Qingdao, Shanghai China or other seaport |

||

|

Shipment Terms: |

FOB, CFR, CIF |

||

|

Production Capacity: |

250000 set |

||

|

Payment Terms: |

L/C, T/T, D/P |

||

|

Connection: |

Flange |

||

|

Flange Material: |

Carbon Steel, Stainless Steel |

||

|

Period of Delivery |

about 21 working days |

||

|

Packing: |

cartons, boxes or Plywood cases, or packing as per the buyer’s requirements |

||

|

Product Logo: |

LIDE or buyer’s logo, trademark |

||

|

HS Code |

4016999090 |

||

|

SPOOL TYPE (ST) -American Standard ST |

||||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||||

|

Pipe Size |

O'all Length |

Flange OD |

Retaining Ring Thickness |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

Inch |

Inch |

|||

|

2" |

50 |

6" |

6" |

3/8" |

7/16" |

1/4" |

±1/2" |

19° |

150 |

26 |

|

2 1/2" |

65 |

6" |

7" |

3/8" |

7/16" |

1/4" |

±1/2" |

15° |

150 |

26 |

|

3" |

80 |

6" |

7 1/2" |

3/8" |

7/16" |

1/4" |

±1/2" |

13° |

150 |

26 |

|

4" |

100 |

6" |

9" |

3/8" |

7/16" |

1/4" |

±1/2" |

10° |

150 |

26 |

|

5" |

125 |

6" |

10" |

3/8" |

7/16" |

1/4" |

±1/2" |

8° |

150 |

26 |

|

6" |

150 |

6" |

11" |

3/8" |

7/16" |

1/4" |

±1/2" |

6° |

150 |

26 |

|

8" |

200 |

6" |

13 1/2" |

3/8" |

11/16" |

3/8" |

±1/2" |

6° |

150 |

26 |

|

10" |

250 |

8" |

16" |

3/8" |

11/16" |

3/8" |

±1/2" |

5° |

150 |

26 |

|

12" |

300 |

8" |

19" |

3/8" |

11/16" |

3/8" |

±1/2" |

5° |

150 |

26 |

|

14" |

350 |

8" |

21" |

3/8" |

11/16" |

3/8" |

±1/2" |

4° |

150 |

15 |

|

16" |

400 |

8" |

23 1/2" |

3/8" |

11/16" |

3/8" |

±1/2" |

4° |

150 |

15 |

|

18" |

450 |

8" |

25" |

3/8" |

11/16" |

3/8" |

±1/2" |

3° |

150 |

15 |

|

20" |

500 |

8" |

27 1/2" |

3/8" |

13/16" |

7/16" |

±1/2" |

3° |

150 |

15 |

|

24" |

600 |

10" |

32" |

3/8" |

13/16" |

7/16" |

±1/2" |

3° |

150 |

15 |

|

SPOOL TYPE: FILLED ARCH (STF) -American Standard STF |

||||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||||

|

Pipe Size |

O'all Length |

Flange OD |

Retaining Ring Thickness |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

Inch |

Inch |

Inch |

Inch |

Inch |

Inch |

|||

|

2" |

50 |

6" |

6" |

3/8" |

7/32" |

1/8" |

±1/4" |

9.5° |

150 |

26 |

|

2 1/2" |

65 |

6" |

7" |

3/8" |

7/32" |

1/8" |

±1/4" |

7.5° |

150 |

26 |

|

3" |

80 |

6" |

7 1/2" |

3/8" |

7/32" |

1/8" |

±1/4" |

6.5° |

150 |

26 |

|

4" |

100 |

6" |

9" |

3/8" |

7/32" |

1/8" |

±1/4" |

5° |

150 |

26 |

|

5" |

125 |

6" |

10" |

3/8" |

7/32" |

1/8" |

±1/4" |

4° |

150 |

26 |

|

6" |

150 |

6" |

11" |

3/8" |

7/32" |

1/8" |

±1/4" |

3° |

150 |

26 |

|

8" |

200 |

6" |

13 1/2" |

3/8" |

11/32" |

3/16" |

±1/4" |

3° |

150 |

26 |

|

10" |

250 |

8" |

16" |

3/8" |

11/32" |

3/16" |

±1/4" |

2.5° |

150 |

26 |

|

12" |

300 |

8" |

19" |

3/8" |

11/32" |

3/16" |

±1/4" |

2.5° |

150 |

26 |

|

14" |

350 |

8" |

21" |

3/8" |

11/32" |

3/16" |

±1/4" |

2° |

150 |

15 |

|

16" |

400 |

8" |

23 1/2" |

3/8" |

11/32" |

3/16" |

±1/4" |

2° |

150 |

15 |

|

18" |

450 |

8" |

25" |

3/8" |

11/32" |

3/16" |

±1/4" |

1.5° |

150 |

15 |

|

20" |

500 |

8" |

27 1/2" |

3/8" |

13/32" |

7/32" |

±1/4" |

1.5° |

150 |

15 |

|

24" |

600 |

10" |

32" |

3/8" |

13/32" |

7/32" |

±1/4" |

1.5° |

150 |

15 |

Our production process quality control

We treasure process quality control, there is very strict operation specification each process, which can ensure the goods quality:

1. We use electronic weigher to weigh the weight of ingredients, the precision of weight is gram. So there is no surplus compounds elements;

2. 1.) By controlling material temperature and mixing time in the mixer machine, we can get qualified rubber mixed composites.

2) The calender process is the more critical phase, large steel rollers force rubber composites into smooth rubber sheets.

3)The rubber sheets produced every day must be finished within the same day, we can ensure no rubber sheet remainder each day.

4) All rubber sheets have passed the test of curometer.

3. Adding adhesion agent in the mixture of rubber and nylon tire cord, then the rubber and nylon tire cord can be adhered together and turn into the integral. After vulcanization, all the rubbers are adhered tightly, it is very difficult to delaminate.

Below is the pictures of plastic sheet combined with rubber and nylon tire cord:

4. In wrapping process: all the elastomer constructions are made by hand-built and machine. After hand-builting, the underneath pressing roller moves along the elastomer body and compact the rubber sheets. There are two main functions of the roller, one is compacting the rubber sheets and making the rubber sheets more bonded, the other one is extruding air between rubber films. So it is very difficult to generate blisters and delamination after vulcanization.

5. After vulcanization, there are 4 inspection processes: first qualified products inspection, trimming, assembling process, inspection for finished goods, if the goods with blisters are found then scrap.

Our certificates

Our workshop

Our Test instruments

Hot-aging oven

Electronic Universal testing machine

hydrostatic test

Rotorless Vulcanizer

Low Temperature Testing Oven

Digital density balance

FAQ

1. Does the company accept to show buyer’s logo?

Yes, we can accept buyer’s logo or their trademark.

2. What is the material of the products?

The flange materials are carbon steel and stainless steel, the materials of rubber elastomer are EPDM/NBR/SBR/NR/Butyl/Neo/Lined with PTFE.

3. Does the company have approvals or certificate? If yes, what are they?

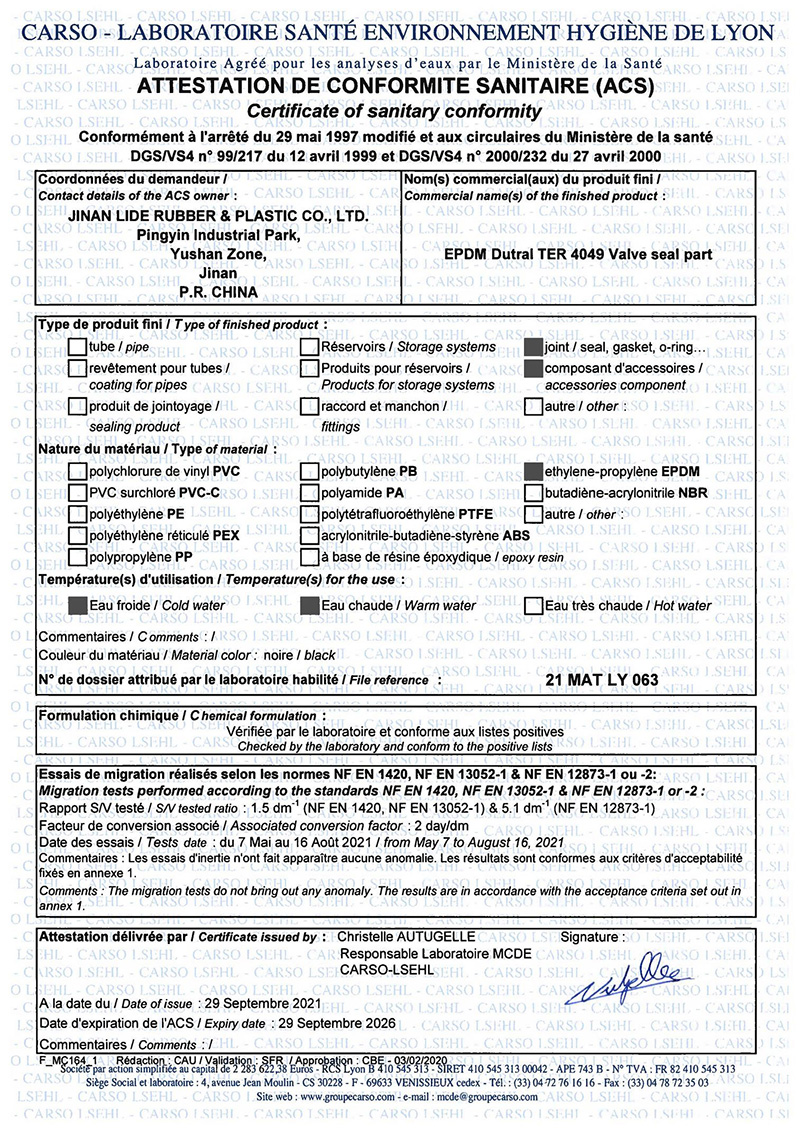

Yes, we have approvals, such as CE, Wras,ACS, ISO9001 certificate.

4. What is the average lead time for delivery?

Our average lead time for delivery is between 3-4 weeks, from getting deposit or getting copy of LC.

5. Does the company have the minimum order quantity requirement? If yes, What is it?

We accept minimum order quantity with 1 full pallet.

6. What is the acceptable payment method?

We can accept T/T, L/C and D/P. Any other different payment method, we can talk further.

7. Does the company have their own brand?

Yes, we have our own brand, LD logo.

8. What is the advantage of the price-quality ratio?

Yes, the price of our goods is more competitive, it is much cheaper, but the quality is much better.

9. Does the company have product liability insurance?

Yes, we can supply if required.

10. Does the company accept to OEM brand?

Yes, we can accept buyer’s logo or their trademark.

11. Does the company accept to supply samples?

Yes, we can accept samples, by DHL or other courier express.